ECONOMICAL AUTOMATIC CUP MASK MACHINE

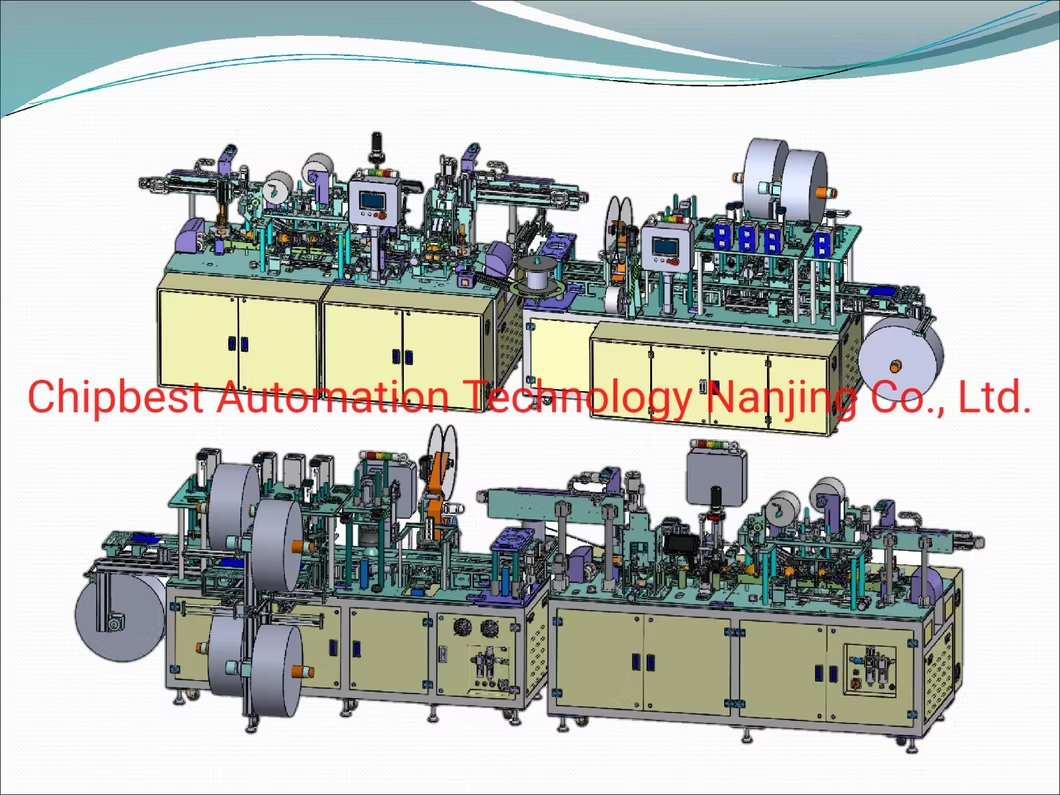

Overall Appearance

Overall Appearance

1.Function Introduction:

This equipment is used for automatic cup mask production line (typical model, such as N95 mask). The equipment is used for feeding the whole roll, multi-layer spunlace cloth, dissolving spray cloth and non-woven fabric rolls through hot pressing, overlapping cold pressing, ultrasonic welding and fusion, automatic pasting of foam, and finally cutting and forming the mask, automatic hot pressing of nose bridge and automatic welding of ear straps into finished products. The production of masks is

comfortable to wear, no sense of pressure, good filtering effect, fit the shape of human face, can be applied to medical,electronics, mining, construction and other industries.

This machine adopts PLC, touch screen control, main conveyor belt adopts imported servo motor transmission, accurate transmission, stable control, adjustable speed.

2.Product Characteristics:

1. The whole line is fully automated, with a production speed of 15-20PCS per minute, and can be produced without shutdown during feeding.

2. Melt spray can be cold pressed, the product quality can reach FPP3 grade

3. Automatic paste sponge strip, accurate and beautiful position.

4.The equipment is easy to maintain, modular design, can be quickly spliced, to achieve rapid production.

5. The equipment size is small, 3000*2000*1800/3000*1500*1800mm covers an area of less convenient air transport.

6. Each module can be used separately, free combination.

7. The processing workpiece aluminum alloy hard oxygen processing, the frame adopts cast iron welding, baking paint, beautiful, solid and not rust.

8. PLC(Mitsubishi PLC) programming control, high stability, low failure rate, less noise.

9. Adopt imported servo motor, imported pneumatic components, high precision.

10. The material size is small, photoelectric detection of raw materials, avoid mistakes and reduce waste.

11. The machine adopts pulley and fixed foot, which is convenient and fast to move, strong and fixed, and does not waver.

3.Technical Parameters:

1. Machine size length width height: 6000mm*2050mm*1800mm can be split into 3000*2000*1800/3000*1500*1800mm two parts

2. Weight: Total weight 2.3T 1.3T/1.0T after splitting

3. Voltage: AC380V 50-60Hz

4. Production efficiency: 15-20 pieces/min

5. Power: 20KW

6. Air consumption: 35m³/min Air pressure 0.6Mpa (suitable for 22KW air compressor).

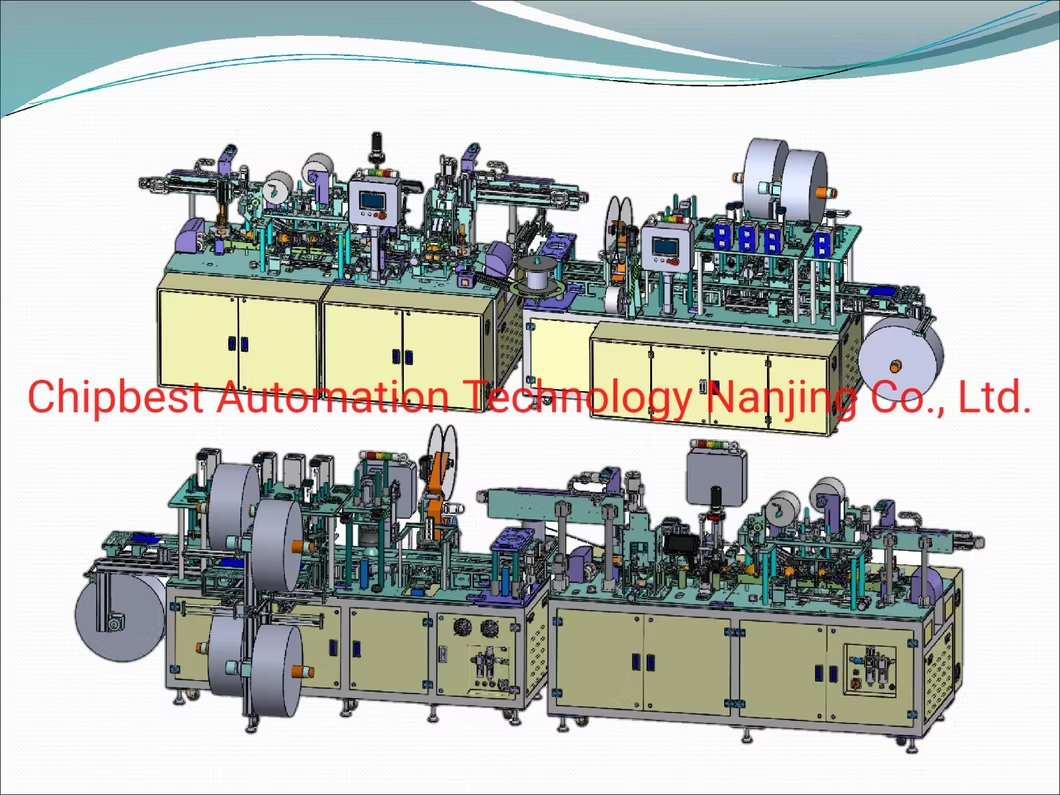

Overall Appearance

Overall Appearance1.Function Introduction:

This equipment is used for automatic cup mask production line (typical model, such as N95 mask). The equipment is used for feeding the whole roll, multi-layer spunlace cloth, dissolving spray cloth and non-woven fabric rolls through hot pressing, overlapping cold pressing, ultrasonic welding and fusion, automatic pasting of foam, and finally cutting and forming the mask, automatic hot pressing of nose bridge and automatic welding of ear straps into finished products. The production of masks is

comfortable to wear, no sense of pressure, good filtering effect, fit the shape of human face, can be applied to medical,electronics, mining, construction and other industries.

This machine adopts PLC, touch screen control, main conveyor belt adopts imported servo motor transmission, accurate transmission, stable control, adjustable speed.

2.Product Characteristics:

1. The whole line is fully automated, with a production speed of 15-20PCS per minute, and can be produced without shutdown during feeding.

2. Melt spray can be cold pressed, the product quality can reach FPP3 grade

3. Automatic paste sponge strip, accurate and beautiful position.

4.The equipment is easy to maintain, modular design, can be quickly spliced, to achieve rapid production.

5. The equipment size is small, 3000*2000*1800/3000*1500*1800mm covers an area of less convenient air transport.

6. Each module can be used separately, free combination.

7. The processing workpiece aluminum alloy hard oxygen processing, the frame adopts cast iron welding, baking paint, beautiful, solid and not rust.

8. PLC(Mitsubishi PLC) programming control, high stability, low failure rate, less noise.

9. Adopt imported servo motor, imported pneumatic components, high precision.

10. The material size is small, photoelectric detection of raw materials, avoid mistakes and reduce waste.

11. The machine adopts pulley and fixed foot, which is convenient and fast to move, strong and fixed, and does not waver.

3.Technical Parameters:

1. Machine size length width height: 6000mm*2050mm*1800mm can be split into 3000*2000*1800/3000*1500*1800mm two parts

2. Weight: Total weight 2.3T 1.3T/1.0T after splitting

3. Voltage: AC380V 50-60Hz

4. Production efficiency: 15-20 pieces/min

5. Power: 20KW

6. Air consumption: 35m³/min Air pressure 0.6Mpa (suitable for 22KW air compressor).